|

|

|

| Summary | Latest news | Working Party reports | Working Party dates | CAD Drawings | Archived news and reports |

When this current spell of restoration work started in 2008 the loco was initially based in a building known as the 'Clip Shed' at Dinas where it was fully dismantled and where much of the activity was concentrated in the early stages of the project. Here the remaining components were removed and together with those that had already been taken off these were inspected and an assessment made on what was needed towards their full refurbishment.

The main frames were shot blasted and painted and major components such as frame stretchers and drag boxes were either repaired or replaced. The cylinders have been re-aligned by re-boring them in-situ.

The boiler for №134 was kept outside in the North Yard at Dinas as can be seen in the left photograph below, although it was subsequently moved to be less in the way of the site's other activities as seen centre below. The tubes had previously been removed and the boiler barrel and firebox thoroughly inspected for assessment of the work needed. In December 2018 the boiler was moved to Locomotive Maintenance Services (LMS) in Loughborough - right hand photo below.

|

|

134's boiler at Dinas in

January 2009 (left) and September 2018 after repainting (centre).

Being

loaded to be sent away for overhaul in December 2018 (right - Photo:

Chris Parry).

In early 2021 the boiler had a further inspection at LMS and work commended to remove the known wasted material. This then enabled a further and more detailed inspection to take place and a plan of work agreed between the the boiler inspector, the railway and LMS. This plan was subsequently put into action in June 2021 with the commencement of the full boiler overhaul.

In the early stages we also progressed work on the tender as funding had been made available for the construction of a new body with the original being life expired. The new tank was duly delivered in April 2012 and after delivery resided on NG15 №133's chassis whilst our own was being refurbished. With №134's chassis complete the tender body was moved over onto its own chassis during the May 2022 working party.

In late 2013 the loco frames were moved to the main Loco Shed at Dinas where the restoration continued for a few more years. Once the loco was on its main driving wheels it was moved out of the Loco Shed to reside in the carriage shed in the North Yard where work continued, mainly on the refurbishment of other components including the pony truck assemblies. The group had use of a workshop nearby and next to our original home in the Clip Shed and it is here where all the components were overhauled and kept until needed.

An Injector Check Valves being refurbished (left) and a coat of gloss for the axlebox covers. (right).

In February 2019 the frames were moved back into the Loco Shed. Here the main driving wheelsets were removed and taken for further work to be carried out by contractors. Also the pony trucks went to Boston Lodge for further contract work to be carried out on them there.

|

134's main frames in the Loco Shed, March 2019. (Photo: Huw Jones).

Unfortunately then along came the Covid-19 pandemic and all volunteer work on the loco had to stop, other than the odd homework project. The full time staff were still in action though and in early 2021 they re-wheeled №134 for us to enable it to be moved around more easily as more space was needed in the Loco Shed for some extensive work required on the NGG16 service Garratts. Once the pandemic restrictions started to be lifted we were then able to hold our first full working party for 14 months in April 2021. This involved us moving into the Goods Shed where we had sufficient space to be able to work on the loco and tender in the short term.

After this, and once room had become available in the loco shed again, we were able to move the tender and frames back in there. Here progress continued on both the loco frames, and associated components, and on the tender frames and its body. The interface between the loco and the tender, the area of the cab, was looked into in more detail and further revised from the original plans.

|

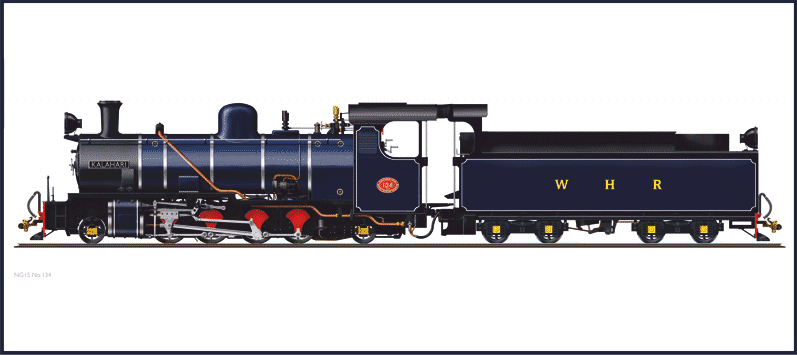

A view of 134's revised appearance with the new dome position.

Work was going on in the background by the full time staff both at Dinas and Boston Lodge where things like the motion was being overhauled, a new frame extension for the cab floor made to mention two areas.

As previously mentioned above, working in parallel to all the activity on the tender and frames the boiler was also overhauled at Locomotive Maintenance Services in Loughborough. This took place steadily from the early 2021 up until late 2022 when it passed its steam pressure test there. The boiler was then delivered to Dinas and lowered into the frames in January 2023.

|

The boiler after being fitted into the frames at Dinas. Photo: Ben Abbott

After the fitting of the boiler, the loco was taken for a short ride along the line with a wooden mock up of the cab in place prior to the real cab made. This has since been manufactured and is now at Dinas and being fitted to the loco.

In parallel to this and providing the next most visible signs of the progress being made is the shaping and fitting of the boiler cladding together with the attachment of the boiler insulation. This is being steadily progressed during the 2023.

The completed boiler barrel section of the cladding.

Out of sight jobs on the tender and loco progressed, including things like the brake rigging and the fitting of the ashpan drenching system.

For those wanting to help,

working parties are held

monthly at Dinas. See the Working

Party Dates page for details of when

№134

is being worked on and how to get involved.