|

|

|

| Introduction | Frame shotblasting | Wheel tyre turning | Tender tank | Rear frame stretcher | Loco Rear Dragbox | Boiler Overhaul |

Introduction

The rear dragbox, from its quite descriptive name, is the fabrication at the rear of the frames that takes the load from the tender and the rest of the train. It therefore has to be quite a substantial structure - unfortunately time and subsequent corrosion has left the structure quite compromised as far as its designed strength is concerned! With that in mind, and with the revised loco to tender interface being planned it was decided there was a need to replace this fabrication.

Following the re-fitting of the refurbished rear frame stretcher the removal started on the old rear dragbox at the Jone 2012 working party with its final removal taking place at the following working party in July . Pictures from the working party are available here. The new dragbox was fabricated by Brinswick Ironworks who have helped us on quite a few items of 'contract work'.

The story is taken up below as it happened.....

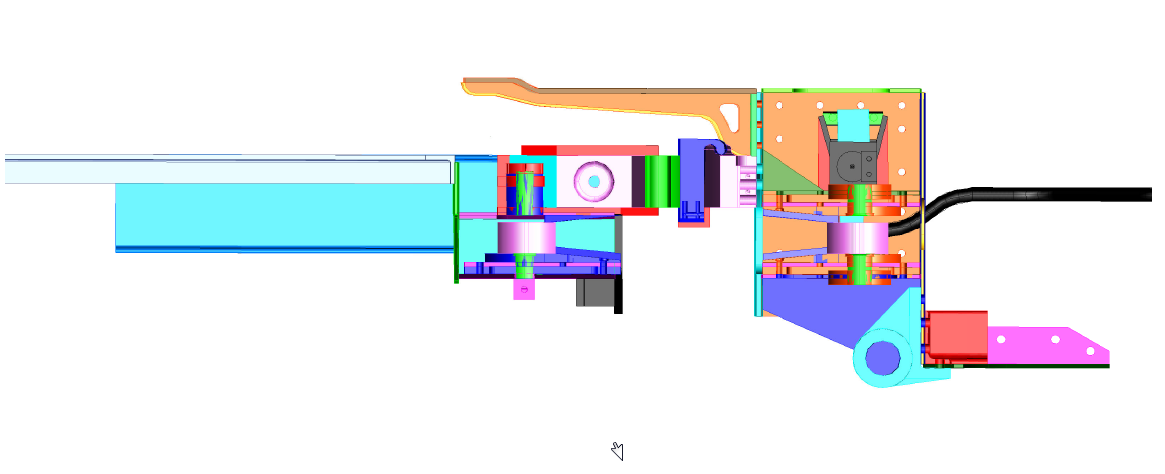

The loco's rear dragbox - Coupling drawing

The following image for the techinally minded is a sectional view of the loco to tender connection being incorperated into the rear dragbox.

|

The loco's rear dragbox - January 2013

Work has started on the replacement rear dragbox for the loco. The original was life expired due to a considerable amount of corrosion being present in its structure. Whilst the original was of piecemeal construction with each section of the box being fitted and riveted into place between the frames, the new dragbox will be of all welded construction. It's being build by Brunswick Ironworks in Caernarfon and will be built in their workshops as a single unit. It will then be accurately machined prior to being fitted into the frames at Dinas.

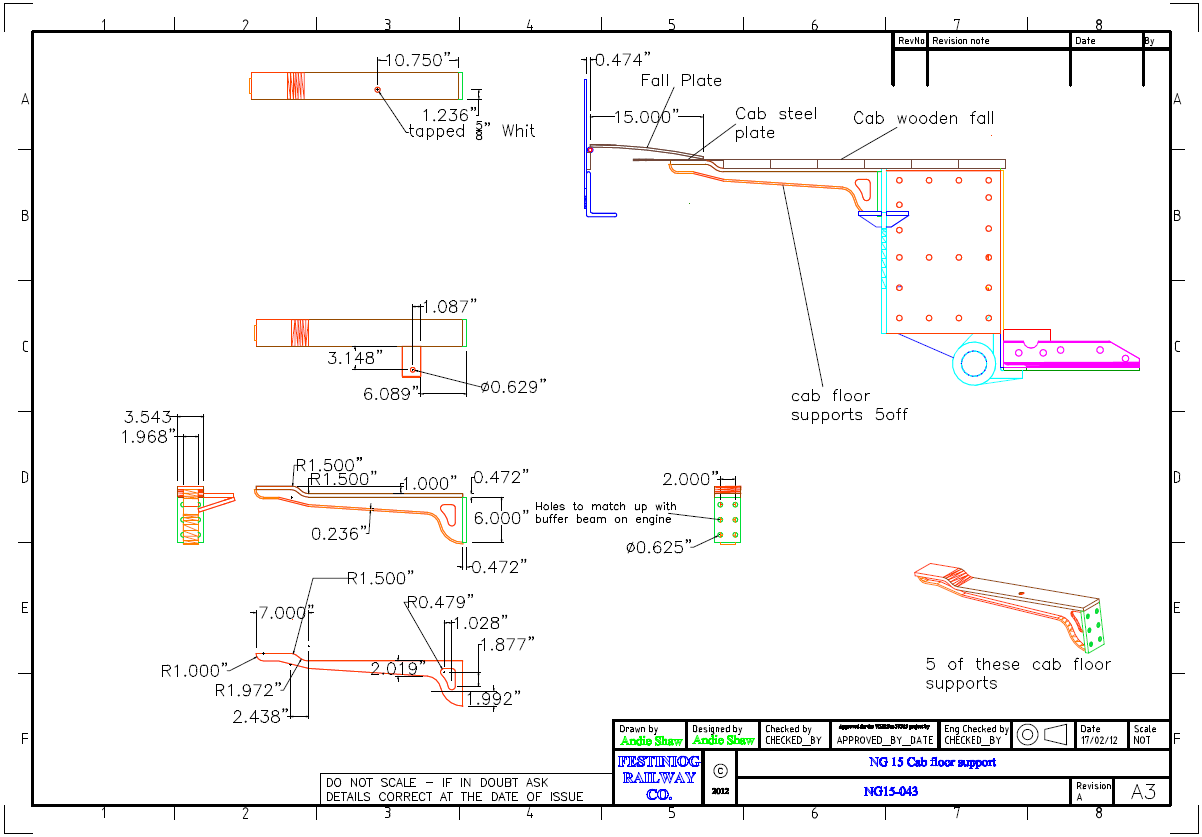

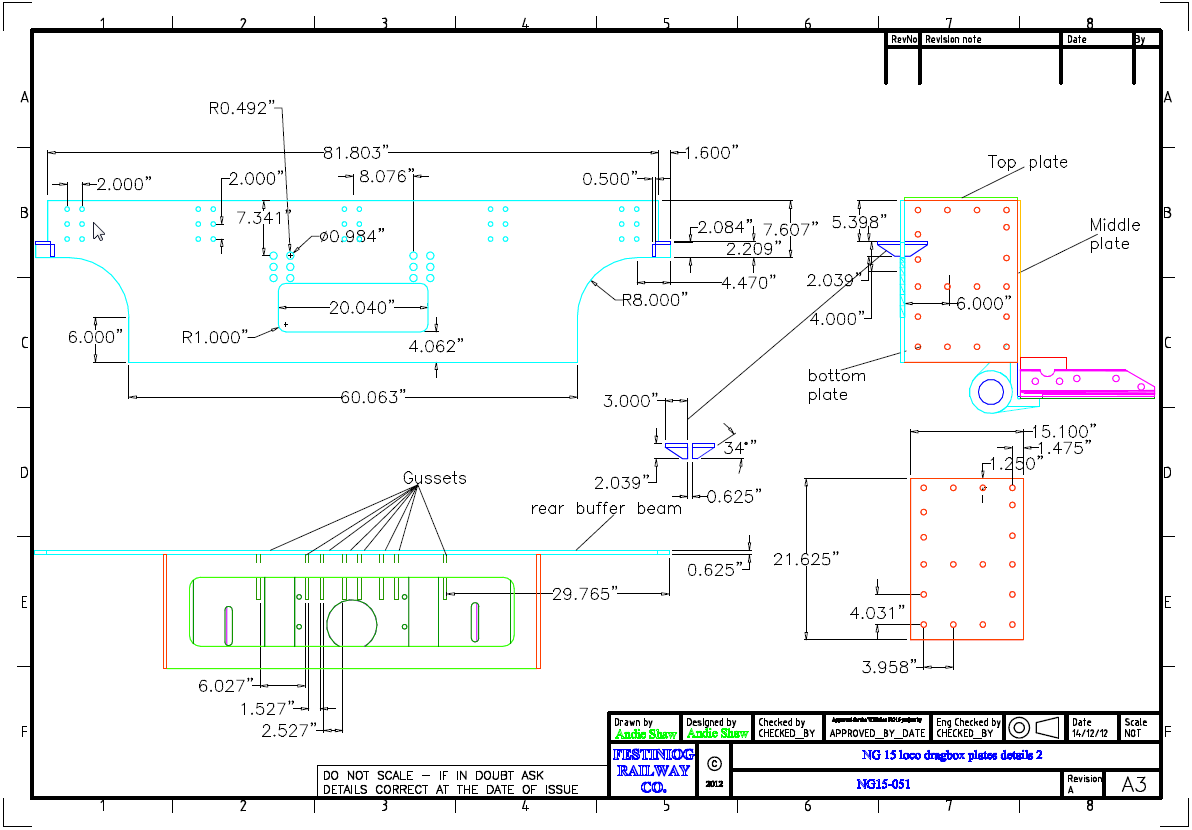

The drawings were given to Brunswicks early in the new year and as soon as more details are know we'll keep you informed of progress though this page. Some details of the dragbox are shown in the rationalised drawings below.

|

|

Click drawing for larger image

Progress to May 2013

During the May working party a visit was paid to Brunswick Ironworks to see the new dragbox under construction. Whilst some parts were fully welded the majority of the unit was just just 'tack' welded to check for fit and functionality. Once complete the assembly will go to the Ffestiniog Railway's Boston Lodge Works for machining to be an accurate fit between the frames.

|

The new rear dragbox being constructed by Brunswick Ironworks.

Progress June 2013

On June 8th the rocking grate operating mechanism was being fabricated inside the dragbox before the whole unit is finally fully assembled and welded. It's expected to go to Boston Lodge Works for machining during the second week of June.

|

The rocking grate operating mechanism being fitted inside the dragbox.

Progress end July 2013

At the end of July 2013 the dragbox was being worked on at the Ffestiniog Railway's Boston Lodge Works. This involved machining the two side faces that go between the frames. The machining will ensure that it is an accurate fit and will be square to the frames. Once complete the dragbox will be fited into the frames and attached using fitted bolts in the same way as was the rear frame stretcher.

|

The new rear dragbox being machined at Boston Lodge Works.

10th October 2013 - drag box now fitted to Frames

It was reported to us on the 10th October that the drag box had now been fitted to the frames and was in the cource of being secured by fully fitted bolts. The photographs in the Gallery taken on the 12th October show the status of fiting these.

|

The new rear dragbox being fitted into the frames.