|

|

|

| Summary | Latest news | Working Party reports | Working Party dates | CAD Drawings | Archived news and reports |

The Mayl 2025 Working Party and Update

A rather belated update following the May working party.

A smallish group this time, especially on the Sunday but progress achieved nevertheless. The most concentrated effort was Erle machining the oval cab front windows with one of the casting spending most of its time over the weekend on the miller. This is just one of the four casting that make up the two windows so there's still much work needed on the remaining three castings. We do however have the first incarnation of these windows in place in the cab front although these do not open as the new ones will.

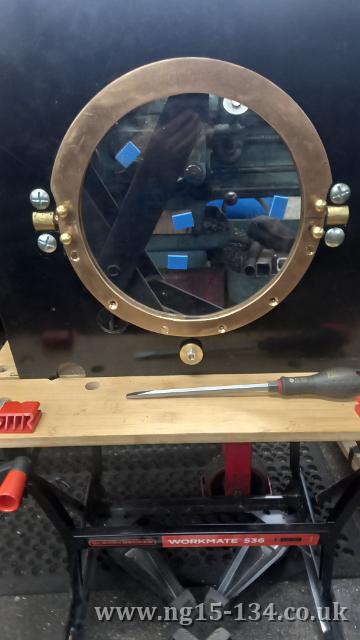

One of the four front oval window castings being machined (left) and

the driver's side rear sanders just needing the sand pipe connecting. (right).

A good few looses ends tidied up such as paint the tender brake gear adjusters in red to indicate which ones are adjusted to remove slack in the linkage. Following the use of front sanders we are happy that they work fine so these were permanently fixed into position rather than on the clamp arrangement we installed to make sure the system worked OK. On the rear sanders, the only item remaining is the plastic tube to take the sand from the trap to the steam operated jets. We did get some plastic tube however, it turned out to be a bit too small and too much of a challenge to fit over the hose-tail ends as these were a bit bigger in diameter than expected.

We also took the opportunity to clean out the smokebox and fit another blastpipe nozzle, one with a slightly larger flow area as we were wondering if we have a bit too much back pressure in the cylinder exhaust.

Another job completed was to make the slide-bar side oiling pad holders. We don't have these pads fitted as yet, however after the weekend this can now be done.

A productive weekend with more jobs ticked off the list.

Easter 2025 Update

Over the Easter period following the April working party a number of the teal spent a number of days at Dinas working on 134 with the intention of tiding up some of the 'loose ends' ready for 134 to start earning is keep on it's first revenue earning train, namely the 2025 Snowdonian. This was taking place on the Saturday after Easter. As part of this exercise, on the Wednesday before we took the opportunity of taking 134 on a short test run. This entailed meeting the day's service train after it had returned to Caernarfon and hauling it back up the hill to Dinas. Needless to say it all went very well.

Part of the reasoning behind this was that we had replaced the grate over the Easter holidays as we weren't entirely happy with the fit of the original. We'd also done some changes to the ashpan drench to get more a more even flow of water into the ashpan.

After Easter we continued with the fitting the rear sanders by plumbing in the last of the steam pipework.

|

The two front round windows in place (left - Photo: Erle Ford) and

taking water at Caernarfon whilst we wait for the return of the service train (right).

Also at the same time Erle was continuing with the machining and fitting of the front windows. At present we've and older incarnation of the frames as a temporary measure and because we weren't happy with them we has some new casting made. These are the ones we're currently working on. By the end of the week both round spectacle plates had been fitted in place, and very smart they look.

The April 2025 Working Party and Update

With Easter approaching it was just a small group of us this weekend as a number of others in the group will be doing work on the loco over the Easter holiday.

A number of jobs over the weekend involved attending to some of the 'snagging list' items that have reared their head since we started to run the loco. One of those involved attending to a few things in the grate and ashpan following the various test runs and photo charter days. On the Friday therefore the grate was taken out so on the Saturday we then prepared a few new sections ready for when the grate needs to go back in.

Another of those snagging jobs was to re-route the last 300mm of the steam pipe run to each of the front sanders as this was showing signs of it being trapped by the sander bracket on the sharper radius curves.

|

A finished and mounted rear sander brackets (left),

and

one of the new pins in place for the blow-down valve linkage (right).

On the new jobs, the main one was the completion and fitting of the mounting brackets for the rear sanders. These sanders are mounted similar to those on the front in that they are fitted on the rear pony truck frame thus they require a flexible connector for the steam pipe. The fixed end needs a bracket mounting on the underside of a frame stretcher and so this was duly made, painted, its mounting position determined and the holes drilled ready for it to be fixed in place next time.

At the last working party one of the team machined a pair of pins to replace the bolts currently being used to attach the blow-down lever from the cab to the crank that operates the valves. This weekend they were fitted and painted. Another little tidy-up job complete.

Work continued on the cab side windows. These are being made with laminated stainless steel frames with the glass sandwiched in the middle layer. Much drilling and tapping of holes was needed for these, however, the last one was finished off on the Saturday. These are now safely stored out of harms way until we needs to fit them.

Another of the tidying up jobs was the painting of the brackets to hold the front rail head sweepers and the new door stops that have been fitted to the tender filler doors to stop them opening too far.

|

The rail head sweapers with their newly painted brackets.

All told, a small group but much achieved from the weekend.

The March 2025 Working Party and Update

Much has happened since the last working party, particularly regarding 134 being quite 'active' out on the main line.

This started with a series of photo charters on the 7th to 9th March with these being followed by a further gauging run, this time getting as far as Nantmor. More details about these are available on the Latest News page.

However, there was also the the March working party for which the detail will follow here.

Not one the biggest of attendances for a working party, but nevertheless much progress was achieved toward finishing off the final few jobs. However as NGG16 No130 was occupying the pit road in the two road loco shed when we arrived on the Saturday during the day we swapped it and 134 round so as we could make use of the pit to work on the installation of the rear sanders.

Over the weekend the two clamps were made that are to be used to attach the two sanders to the rear pony truck in the same way as the front sanders are attached to the front pony truck. Whilst these were being made the steam pipework needed for them was also progressed. Not an easy task with this being one of the last sections of piping to be put in place so it has to find a route through all the other pipes and fitting already in place!

|

The finished rear sander

mounting brackets after painting (left - Photo: Maff Wellman),

and

a completed window frame with some of the components for the remaining

frames (right).

Another large job being progressed this weekend was the assembly of some of the windows for the cab. In this case it's the two screen windows behind the driver and fireman's positions in the cab to provide some protection for reverse running together with the two pairs of sliding windows for the cab sides. These are stainless steel frames and are made of of three laminated sections with the inner layer also holding the toughened glass. There's quite a lot of drilling and tapping to be done to hold the three layers together, and for those of you who have worked with stainless steel, it's not always the easiest of materials to work with!

One thing that we realised we were missing following the experience of the trial runs was a latch to keep the tender door open to make it easier to see in the tender once the coal level dropped to a low level. A suitable latch was duly made and awaits welding into place.

A few other smaller jobs were also progressed, such as a fresh coat of paint being applied to the chimney as it had started to flake off in a few places. The whole chimney was given a rub down followed by a fresh coat of paint, well as much as we could give it until the paint ran out. L

The ashpan was also cleaned out as we're looking at putting a few more holes into the ashpan drench pipework to keep the ashpan a bit cooler.

At present the blowdown valve cranks just have a bolt as their pivot, so a pair of pins were made on the Sunday to neaten this up. They'll be fitted next time.

Last job of the day was to put 134 and 130 back where we found them, and take the opportunity for a team photo, well with those who were left at the end of the day:

|

Sunday's 'team photo' taken as were were putting 130 and 134 back where we found them on the Saturday. (Photo: Ben Abbott)

Main February 2025 Working Party Update

This working party was more about preparing the loco for its second load test on the Sunday with the result that there are only a few photos in the gallery from the work done, but you'll find plenty from the run on Sunday in the Latest News section.

We had a few jobs that need attention with regards to the preparation for the run, such as reattaching a sand pipe for the front sanders that was the casualty of hitting a branch last time and identifying and fixing a 'knock' that we'd noticed on the last run. All proving not to be 'show stoppers' thus allowing us to go out for the next test run.

On the continuing jobs front, with the front sanders complete, work started on the rear sanders by way of starting to make the brackets to support the sanders. Also the pipework for the steam supply run was started.

|

A view showing one of the new window frames on the miller. Photo: Erle Ford

Erle is continuing work on the window frames, as seen above, but spent the Saturday at Boston Lodge using the millers there due to those at Dinas being in use. On Sunday he then finished with the final fitting of the pin fastening the grate opening arm to the lever into the cab. All jobs going towards the loco being fully completed.

Early February 2025 Working Party Update

On the first day of February a small group from the team assembled at Dinas with the intention of getting 134 ready for a first loaded test run. The majority of the work concentrated on getting the front steam sanders finished and working.

To do this, all that remained was attaching a bracket onto the pony truck frames on each side - these had been made in previous working parties - then attaching the sanding nozzles to them. Also a final section of the steam supply pipe was bent to shape and fitted.

|

|

A view showing one of the

steam sanders in place (left - Photo: Andrew Cole),

and

134 being brought into steam ready for the test

run. (right).

With this done 134 was lit up and readied for the test. This didn't take long as one of the team members had arrived the previous day to warm the loco up.

With that done 134 went off to find some coaches to pull for the test. More of which can be read about in the Latest News page.

The January 2025 Working Party and Update

This was the first working party of the new year after the Christmas and New Year break, although a number of the team were able to work on 134 for a couple of days between the two events. A few jobs were able to be progressed, however this working party provided a good bit of progress towards getting to the bottom of the outstanding jobs list.

The first activity to comment on is that of the window frames. We had a set of castings made some time ago and these had been fitted to the loco without glass, however they were rather too thin to be robust enough. That, together with the hinge casting needing to be a bit stronger, resulted in us deciding to have these remade with new patterns for both the frame and hinge. The existing windows however, were fitted with some acrylic glass this weekend and fitted as non-opening windows to give a bit more protection in the cab for any future trial running we'll do during the winter.

In parallel to fitting the old frames, Erle used this weekend to progress the machining of the new castings as can be seen below.

|

|

The assembled window

before fitting into the dummy cab section (left),

and

This

is one of the new window frames being worked on using a dummy cab

section as a help toward checking it for it's fit (right -

both: Erle Ford).

As part of fitting the front sanders we made a bracket to support the steam sander jets on the front pony truck frame in front of the wheel set. As these now move in relation to the main frames, we also had to make and fit a bracket to support the other end of a flexible coupling that will be used to supply the steam.

I'd arrived the day before the working party to finish off the pipework in the cab for the grate steam, as well as anneling a few more lengths of copper pipe ready to use. The grate steam provides a spray in the ashpan underneath the grate to help keep it a bit cooler to prevent clinker solidifying and sticking to the firebars. There's still more pipework to do so the main working party was spent progressing routing the steam pipework to the front sanders. Just one more length to be fitted next time then, once the sanders are all connected up, we'll be in the position to start putting a load behind 134.

A number of other small 'loose ends' jobs were also completed, so overall the jobs list is getting smaller.

The earlier working party reports going back to 2008 can be found in the Archive